X12MF

Warehouse working hours:

Mon - Thu 9:00 - 16:30

Fri 9:00 - 12:30

EN

Tool steel X12MF

The shape of the steel

The possibility of cutting on band saws to size according to your request. The minimum batch of metal products is from 1 kg

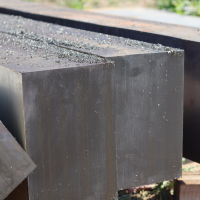

Sheet

Stamped blanks have an integral structure, which is their advantage.

Forging

Volumetric billet. It is used in industry in various fields.

Stripe

A type of high-grade rolled metal having a rectangle shape in cross section.

Steel rod

A type of high-grade rolled metal, which is a round-section steel rod.

Payment and delivery

We work only with legal entities

The form of payment is non—cash payment

Convenient and affordable types of payment

Prepayment, deferred payment

Reasonable payment terms

They are agreed upon for each specific transaction

Call us, we will definitely come to an agreement with you!

Call, write or come

Timely delivery

We carry out delivery in Minsk and all regions

Nice prices for delivery

The cost and delivery time are agreed with the manager

Free shipping is available

We will always offer the best option

Questions and answers

Questions that customers ask us most often:

Ask our specialists a question

Call or send a request for the positions you need

Why choose us

High-quality rolled metal and forgings

Since 1995, we have been specializing in the production of high-quality rolled metal and forgings. We are proud of our reputation as a reliable supplier of high-quality products.

Precise cutting into blanks

The harvesting area is equipped with modern band sawing machines. This allows us to offer materials in the required sizes and shapes that meet your needs.

Efficiency and effectiveness

Time is the most valuable resource, so we strive to ensure fast and efficient work. Production processes are optimized taking into account modern standards for prompt order fulfillment and minimizing delivery time

Large selection of tool steels

There are more than 700 tons of tool steels available. Our specialists are always ready to help you choose the right steel grade and provide advice on its application.

Trust and reliability

We value the trust of our customers and strive for long-term partnerships. We guarantee the quality of the products and are responsible for each delivery.